solution

solution

-

Industrial railway signal control integrated product series

-

GKI-33e all electronic computer interlocking system

-

HJ05A enterprise station dispatching centralized system

-

HJ06A industrial railway dispatching supervision system

-

HJ07A industrial railway logistics management system

-

HJ08B railway locomotive operation safety control system

-

HJ12A torpedo tank tracking management system

-

GKS-37i automatic train monitoring system

-

Intelligent unmanned operating system for hot metal transportation

-

Intelligent maintenance cloud service system

-

HJ08A railway locomotive wireless operating system

-

-

Mine intelligent auxiliary transportation product series

-

KJ293(A) Mine rail transport monitoring system

-

KJ303(A) Coal mine Personnel Management System

-

KT621 wireless communication system for mining

-

KJZ21/KJZ22 mine track electric locomotive unmanned system

-

KJZ16 mine rubber wheel transport monitoring system

-

KJZ17 mine intelligent logistics control system

-

KJZ20 mine integrated automation system

-

KJZ33 mine locomotive and vehicle transportation intelligent dispatching command system

-

KLX8LM(A)KLX6LM(A) Intrinsically safe information mining lamp

-

-

Digital intelligence application builds industry-wide digital intelligent decision making

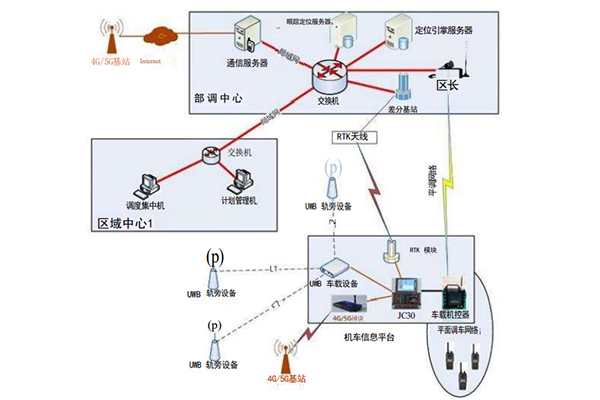

HJ08A railway locomotive wireless operating system integrates many functions such as modern wireless communication, locomotive information platform and plane shunting,Network with centralized scheduling system,Provide comprehensive solutions for railway locomotive operation process,Realize real-time transmission of information from dispatching center to station, locomotive, driver, connector, dispatcher and other production links,It can also monitor locomotive operation status in real time。

The system realizes the electronic monitoring, display and data playback of locomotive working process, and has the functions of signal boarding, operation plan boarding, plane shunting and locomotive safety operation。

GKI-33e all-electronic computer interlocking system is the key technical guarantee equipment to control the interlocking relationship between signals, switches and routes in railway stations, and is the core system to ensure transportation safety and improve the capacity of rail transit railway lines and the ability of station yard assembly。The system can ensure the safe and efficient operation of trains in railway stations and yards,Can be widely used in metallurgy, mining, petrochemical, port, electric power and other industrial railway plant station (including special line and special railway),It has the advantages of high safety, maintenance-free, flexible configuration, simple structure, rich interface, short construction period, large equipment capacity, independent intellectual property rights and so on。

HJ05A enterprise station dispatching centralized system is a set of computer integrated monitoring system used for dispatchers to control and supervise signal equipment and train operation in the command center, and realize centralized control of multi-station and yard。

The system is based on railway signal computer interlocking system and railway logistics management system,The function of station dispatching centralized system is further extended,Generate a shunting plan by dragging or intelligent triggering,Automatic signal prescheduling and plan execution,Complete the management and control integration of planning and signal opening,It has created conditions for the combination of duty and signal personnel,To achieve the purpose of reducing staff and increasing efficiency。

The system is composed of the control center subsystem and each station subsystem, which are connected into a control network through the network transmission channel。The whole system adopts TCP/IP protocol based LAN, computerized distributed system structure;Both the dispatching centralized machine and the communication front-end machine are configured with dual-system hot backup redundancy.The transmission channel between the main nodes of the network adopts the dual-channel design to ensure the security and reliability of the system。

The system has complex technology and high safety requirements, which can save a lot of human resources, and greatly promote the reduction of production safety accident rate and improve operation efficiency。

HJ06A industrial railway dispatching supervision system is a new generation distributed integrated dispatching supervision system for 6502 railway signal electrical centralized system and various standard computer interlocking systems。

The system aims at the current situation of the original electrical centralized system or computer interlocking system,Using advanced fieldbus technology and computer software technology,The state detection of equipment and the insulation state monitoring of signal cable are carried out through the signal monitoring,And the real-time acquisition of logistics data,Realize real-time supervision and management of signal equipment status, train operation status, real-time location of locomotive and vehicle, cargo distribution status of each railway station under the jurisdiction of the dispatching center。

The system adopts advanced acquisition technology, computer communication technology and software technology, and successfully applies modularity and plug and play design idea to signal acquisition design, which can adapt to 6502 and computer interlock system, and the wiring is simple and the construction is convenient。

The system comprehensively displays the operational reality of the industrial railway transport site, provides visualized and integrated data analysis to railway transport management and scheduling personnel at all levels, helps to improve the safety of railway transport scheduling, and is a necessary condition for the integration of enterprise railway transport management and control。

HJ07A industrial railway logistics management system uses intelligent software to automatically generate logistics data,To realize the dynamic tracking and management of the position, status, operation process (including hot metal car, torpedo tank car unhook and disassemble), operation start and end point, operation time and materials transported by the locomotive and vehicle in the industrial railway station,It has the functions of operation schedule prediction, vehicle prediction, and visualization of current vehicle information。At the same time, it can be connected with automatic identification system of vehicle number and wireless operating system of locomotive to improve the automation level of railway transportation business of enterprises。

The system can also realize the operation management of enterprise railway transportation, such as entering/leaving the factory, loading/unloading, vehicle scheduling, etc., and can realize real-time statistical analysis of the transportation production process, generate visual reports, and provide decision-making basis for production scheduling。

HJ08B railway locomotive operation safety control system is a set of industrial railway locomotive safety operation equipment, which can realize accurate real-time tracking, train detection, accurate positioning, running scheduling, running safety monitoring and other functions for the locomotive and its connected vehicles。The system is based on high precision satellite positioning technology, UWB precise positioning technology, track circuit positioning technology, wireless communication technology and Internet of Things,It can realize accurate real-time tracking and precise positioning of industrial railway locomotives and vehicles by means of hardware detection,The functions of wireless transmission of shunting plan, ground signal recurrence and safety monitoring of locomotive operation are realized。

The system can effectively prevent the locomotive from overspeed and ensure that the locomotive stops before blocking the signal。In addition, it can reproduce the locomotive running condition and locomotive running path in an intuitive form on the ground computer, which provides a basis for analyzing the quality of locomotive operation, the quality of electrical equipment and the quality of train dispatching, and provides help for the maintenance department to realize the modernization management。

HJ12A torpedo tank tracking management system is a combination of electronic tag and track circuit technology to realize the position tracking of locomotive and torpedo tank. The system can not only meet the real-time requirements of positioning and tracking, but also realize the automatic matching of torpedo tank status, and realize the information, automation and visualization of the whole process of hot metal transportation and deployment。

The system aims at the reverse flow of hot metal transport,Using torpedo tank as carrier,The data information of ironmaking, steelmaking and metrology are integrated,The interface between torpedo tank tracking system and iron and steel MES system is built,The information integration of torpedo tank receiving iron, reversing transport and steelmaking iron connection is realized,The application of the system can further reduce the transportation time of heavy tank, reduce the drop of iron water temperature, increase the turnover rate of torpedo tank and promote the iron steel balance。

GKS-37i Automatic Train Supervision System,ATS is responsible for the supervision, control and cooperative operation of all subsystems in the intelligent unmanned operating system of the entire industrial railway yard,It is the core command system of intelligent human-machine interaction in industrial railway stations and yards,It collects all scheduling instructions, device status, and environment information,After the analysis of the unified platform,Output control commands for fixed and mobile devices,Including the command of locomotive start and stop and operation, vehicle unhook, signal control, crossing control。The system also has the function of operation safety protection, in the process of automatic operation route, in addition to checking the traditional signal interlock relationship, but also check the pre-set unmanned operating conditions, so as to improve efficiency and ensure production safety。

The system can effectively manage logistics, vehicles and locomotives,It also interacts with the manufacturing execution system (MES), metrology system and inspection/laboratory system of each production process,Realize the whole process of industrial railway transportation deployment informatization, automation and visualization,It is of great significance for the safe and effective realization of intelligent unmanned operation in industrial railway yards。

The system has passed the independent safety assessment of TUV Rheinland, an internationally authoritative third-party certification body,Obtained the international security level SIL2 certificate,It marks a new breakthrough in the field of automatic train operation monitoring technology,In the industrial railway, the deep integration and engineering application of signal system with rolling stock, logistics control and intelligent scheduling are constructed and realized。

The intelligent unmanned operating system for hot metal transportation is based on artificial intelligence and industrial Internet of Things technology,All electronic computer interlocking system, train automatic protection system for safety support,It adopts train precise positioning technology, environmental obstacle identification and detection technology, train automatic driving control technology, vehicle automatic disassembly technology and intelligent scheduling strategy, big data, cloud computing and other technologies,On the basis of the supervision, control and cooperative operation of all transportation equipment in the railway station,Realize automatic train dispatching command and operation with autonomous train driving and remote control functions,Realize intelligent unmanned operation of hot metal transportation,Promote the development of hot metal transportation in metallurgical enterprises from traditional digitalization to intelligent and automated development。It plays a great role in improving the efficiency of railway transportation and ensuring the safety of production in metallurgical enterprises。

All kinds of systems of industrial railways and smart mines have complex structures and a wide range of equipment. In the case of harsh environment, high-strength system use and long-term service, the system operation has the hidden danger of sudden equipment failure, great harm and long maintenance time, which seriously affects production safety and production order。

The intelligent operation and maintenance system developed by the University of Technology monitors the status of equipment/modules in various systems of industrial railways and smart mines in real time,According to the big data platform,Data mining and intelligent analysis through AI-based algorithms,Health prediction and preventive maintenance warning for potential faults,Then provide scientific maintenance plan for maintenance personnel,The traditional "planned repair" of blanket equipment inspection with a fixed period and no scientific maintenance basis will be transformed into a reasonable and intelligent "state repair" mode of on-demand maintenance;Equipment failure,The system can also quickly perform online intelligent fault diagnosis,Quick repair system。The system can also realize the digital management of equipment operation and maintenance, realize the whole life cycle management of equipment, and improve the management level of operation and maintenance work。

Through this system can greatly reduce the railway, mine field equipment maintenance personnel, to achieve the reduction of personnel and efficiency;It can also greatly reduce the failure rate of equipment, ensure safety, and ensure uninterrupted continuous production。

Previous

1

Next page

CONTACT US/CONTACT US

Add: No.1682, Xiyou Road, High-tech Zone, Hefei City, Anhui Province

After-sales service:400-6737788

TOP

Scan and follow us

Copyright © 2021 Hefei High-tech Information Technology Co., LTD. All rights reserved Anhui ICP for 09002995 Technical support: China enterprise power 合肥